3D printing has never been as easy as it is today.

3D printing technology has been around since the early 1980’s but has only become affordable in recent years. What started as a way for manufacturers to develop cheap prototypes of their products has captivated hobbyists into creating all sorts of common household items. Eyeglass frames, clothing, toys, cutlery, and even guns, are all being printed in people’s homes instead of being bought at stores. But this isn’t as easy as you think.

In order to print anything, users must first create or download complicated computer-aided drafting plans to send to the 3D printer. Once the 3D printer has these files, the user must then make adjustments to the extruder, level the build plate, and keep a close eye on the printing process in case something goes wrong. When you factor in the cost of the 3D printer, filament, parts, accessories, and your precious time; 3D printing seems like an expensive and complicated task that only dedicated users can handle. Unfortunately, there is no “Print a (insert item here)” button – but one company is making things a lot easier.

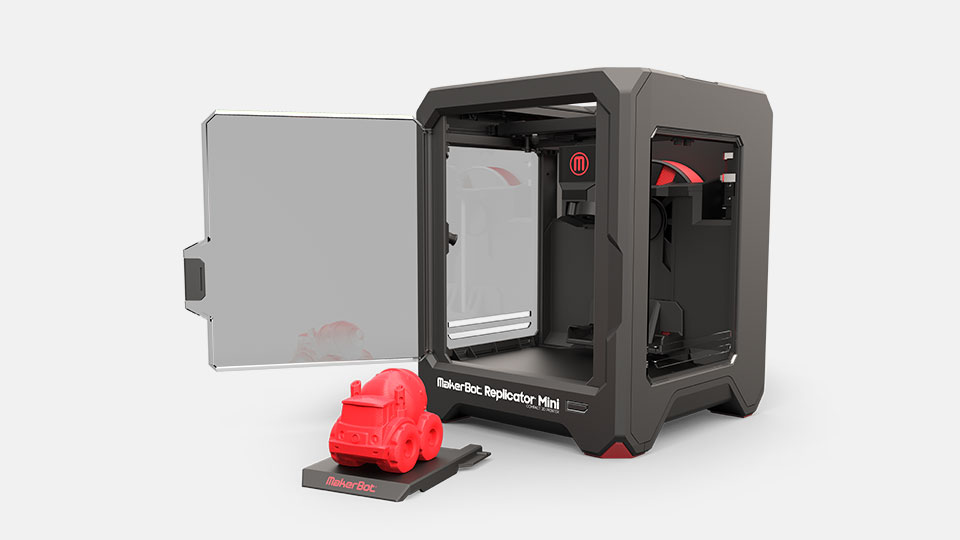

MakerBot, who tout themselves as “leading the Next Industrial Revolution,” released a user-friendly 3D printer earlier this year with the goal of making 3D printing accessible and affordable to everyone. Dubbed the Replicator Mini, this compact printer offers true one-touch 3D printing that doesn’t require any adjustments and even has a camera so you can livestream the printing process while you’re away. All a user has to do is send a file to the printer, press a button, and wait for their objects to print. This tiny 3D printer is as easy as using a microwave, but what truly sets MakerBot apart from the competition is their app store-like website called “Thingiverse”.

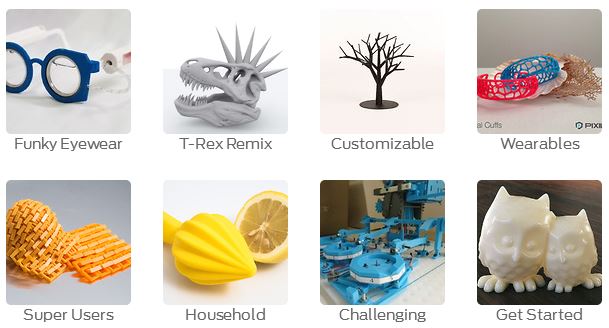

Thingiverse has a huge collection of items you can 3D print.

“The best way to get involved with Thingiverse is to try your hand at 3D designing. Thingiverse isn’t just of designers, engineers, or CAD drawing experts: anyone can learn. But that’s not the only way to participate… Gaining street cred can be as simple as posting your “makes” (prints of an existing design), or creating your own mod template for your favorite 3D design in Customizer, our first app that uses the Thingiverse API.”

— MakerBot

The Thingiverse website serves as an aggregator of everything a person could possibly want to 3D print. Education tools, household items, replacement parts, unique gifts, and more are all available to download and use for free or for a small fee. Thingiverse is a thriving design community that encourages people to not only create 3D objects, but to share what they make with the entire world. This open platform philosophy has led to Thingiverse becoming the world’s largest 3D printing community, but is it the missing link that will one day make 3D printers a common household appliance?

Currently, the Makerbot Replicator Mini retails for $1,375. A half-pound spool of one-color MakerBot-optimized filament (the plastic that is used to 3D print objects) costs between $18 and $25. Depending on the size of the object you want to print, how many colors it will be, and how many you want to print, this can either be very cheap or very expensive.

Recently, the Wall Street Journal wrote a detailed review of the MakerBot Replicator Mini and argued that the items they printed didn’t save them any money – in fact, it cost them time.

The example the Wall Street Journal used was printing two pocket combs that required a free pattern from Thingiverse, $1.65 worth of filament, and two hours of their time. This seems cheap on the surface, but when you consider the price of two pocket combs from a brick-and-mortar store costing roughly the same, it may not be worth the effort or cost of a Replicator Mini to justify the printing. But I think 3D printing should be more than just a way to save a quick buck – it should be about being at the forefront of a new technology that will one day reshape the way we live.

Can MakerBot and its users who are contributing to making 3D printing easier for everyone to use be considered leaders of the next great manufacturing movement? Or are they merely hobbyists who have nothing better to do with their time and money? Only time will tell, but if the Industrial Revolution can teach us anything, it’s that it takes forward-thinking individuals to develop new production processes in order to greatly improve efficiency. The only difference between the year 2014 and 1760 is that now they don’t have to leave their house to do so.